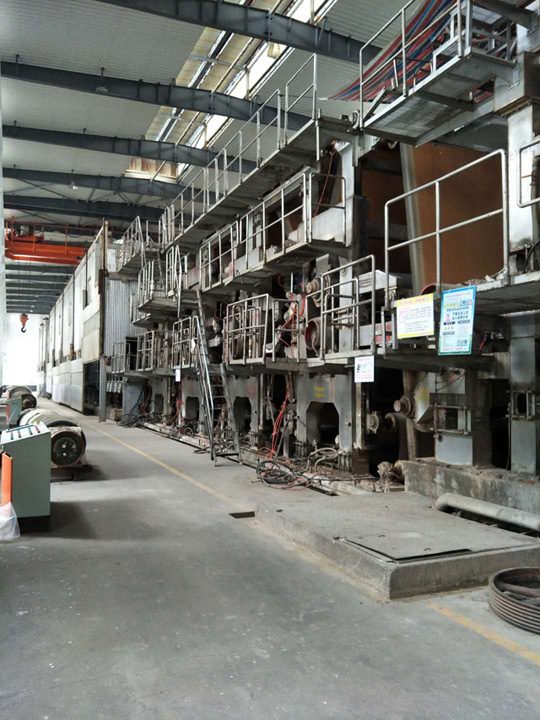

Machine Type: Triple-Wires

Paper Width: 3200 mm trimmed

Year of Made: 2013

Condition: Excellent, power still on

General Data:

Machine Type: Triple-Wires Fourdrinier Machine

Paper Width: Max. 3260 mm (on Pope Reel)

Basis Weight: 120-450 gsm

Paper Grades:

- Ply bond paper (Core tube/Spinning tube base paper)

- Kraftliner

- Testliner

- Fluting media

Machine Speed: 200-350 m/min

Production Capacity:

When making ply bond paper 400 tpd @ 430 GSM

When making Kraftliner 240 tpd @ 150 GSM

Year of Made: 2013

Year of Start-up: 2014

Year of Stop: 2016

Specification of Paper Machine:

Headbox: Pressurized type, 3 Nos. Slice width 3550mm. The stock contacted parts are SS304 construction,

the vertical slice lip is SS316L.

Wire Section: Triple wires structure with cantilevered frame. Wire width 3700mm. The frame is cladded with SS304.

The suction couch roll diameter is 800mm.

Press Section:

- 1st Nip is suction press, double-felted, 60-100 kN/m operating nip pressure

- 2nd Nip is suction press, double-felted, 60-100 kN/m operating nip pressure

- 3rd Nip is jumbo roll press, double-felted, 150-200 kN/m operating nip pressure

- 4th Nip is jumbo roll press, double-felted, 200-250 kN/m operating nip pressure

The suction press roll diameter is 850mm

The jumbo press rolls diameter is 1350mm

The frame is cladded with SS304

Dryer Section:

The pre dryer section consists of 40 Nos. dryer cylinders with diameter of 1800mm.

The post dryer section consists of 12 Nos. dryer cylinders with diameter of 1500mm.

The operating pressure of the dryers is 4.5 bar max.

Size Press: 1 set, conventional pond type.

Hard Nip Calender: 1 set, 2 rolls type.

Pope Reel: 1 set, horizontal automatic reeler with reel spool magazine, max. reeling diameter 2500mm.

Dryer Hood: 1 set, closed type

Slitter Rewinder: 1 set, 900m/min operating speed

QCS: 1 set, radiated type, for basis weight and moisture control

Steam and Condensate System: 1 set, thermo-compressor type

Vacuum System: 5 sets, liquid-ring type vacuum pump

Multi-Wires Section

Press Section